As we approach Memorial Day, a time to honor the men and women who have served our nation, we also reflect on the spirit of American ingenuity and craftsmanship that has defined our history. At Vaer, we are proud to contribute to this legacy through our commitment to American sourcing and assembly. One of the most interesting aspects of this manufacturing effort has been our investment in and integration of FTS Ameriquartz watch movements.

What is an Ameriquartz Movement?

As the name suggests, the Ameriquartz movement is a quartz battery-powered watch movement that is hand-built in America. Specifically, it is produced by our long-time partner Fine Timepiece Solutions (FTS) in Scottsdale, Arizona. As the "engine" of a wristwatch, the ability to incorporate US-sourcing into movement manufacturing is a significant technical achievement and an important step towards a broader US supply chain in horology.

Aside from a small batch of mechanical movement makers and modders, the Ameriquartz is a truly novel product offering and the only USA-built quartz movement on the market today.

A Brief History of American Movement Manufacturing

In the early 20th century, the United States was a global leader in watch movement manufacturing. Brands like Waltham and Elgin dominated the everyday pocket watch market, producing timepieces that were ubiquitous across America. During the mid-20th century, brands like Timex gained significant market share by leveraging advanced USA manufacturing techniques and innovative designs.

In 1956, Timex opened a state-of-the-art manufacturing facility in Little Rock, Arkansas. This plant became a cornerstone of Timex's production strategy, enabling the company to produce millions of watches annually.

In the mid-1960s, Timex further expanded with their manufacturing hub in Durant, Oklahoma. Taking advantage of the skilled labor force and favorable economic conditions, this facility provided stable employment for thousands of residents, contributing to the economic growth and development of the region. Timex's presence also fostered a sense of pride and identity within the community, as workers took pride in producing high-quality American-made watches.

By the late 1980s and early 1990s, Timex, like many other American manufacturers, began to move much of their production overseas. Manufacturing in countries like the Philippines and China allowed Timex to leverage lower labor costs and take advantage of developing manufacturing infrastructure in Asia. Timex ceased all USA-based watch manufacturing in 2001, ending a century-long tradition of affordable USA movement production at scale.

How Difficult is it to Assemble a Quartz Movement?

Today, we are witnessing a significant resurgence of American watch manufacturing, spearheaded by technical teams like FTS and supported by brands like Vaer.

We’re excited to be one of the brands leading the charge with Ameriquartz and helping to raise its profile within the wider community of wristwatch enthusiasts.

While not as technically sophisticated as a full in-house mechanical movement (which would cost millions of dollars in R&D and specialized manufacturing equipment), building quartz movements is still extremely specialized, and assembly of these components is no less challenging. Our FTS Ameriquartz movements consist of 18 meticulously crafted parts, as listed below:

The Anatomy of the Ameriquartz Movement

- Main Plate: The foundation of the movement, holding all components in place.

- Minute Wheel: Transmits motion from the cannon pinion to the hands.

- Cannon Pinion: Connects the minute wheel to the center wheel, driving the hands.

- Center Bridge: Supports the center wheel and second wheel.

- Stator: Part of the motor system that interacts with the rotor to generate movement.

- Klotz: A tiny component aiding in the secure assembly of the movement.

- Klotz Screw: A nearly microscopic screw essential for fastening the klotz.

- Rotor: Rotates within the stator, driven by the magnetic field.

- Third Wheel: Transmits power from the center wheel to the escape wheel.

- Train Wheel Bridge: Holds the train wheels in alignment.

- Train Wheel Banking: Ensures the smooth transmission of power through the train wheels.

- Bridle Screw: Secures the bridle, a spring-like component ensuring battery contact.

- Coil: Generates the magnetic field that drives the rotor.

- ECB Screw: Secures the electronic control board (ECB).

- ECB: The brain of the movement, controlling timing and functions.

- Coil Guard: Protects the coil from damage.

- Battery: Powers the movement.

- Battery Bridle: Ensures a stable connection between the battery and the movement.

Precision Assembly: A Labor of Love

The assembly of our Ameriquartz movements requires a unique skill set and specialized tools. Technicians must operate using loupes and microscopes, employing precision tweezers and screwdrivers to handle components as small as the klotz screw, which can easily rest between the grooves of your fingers. This meticulous process ensures the reliability and accuracy of each movement.

While many of the raw components are currently imported from overseas due to the lack of domestic infrastructure, FTS has made significant strides sourcing USA built electronic control boards (ECBs). With continued support from Vaer customers, we are committed to bringing more component manufacturing stateside, enhancing our capacity to produce high-quality, American-made movements end-to-end.

Reinvesting in American Watchmaking

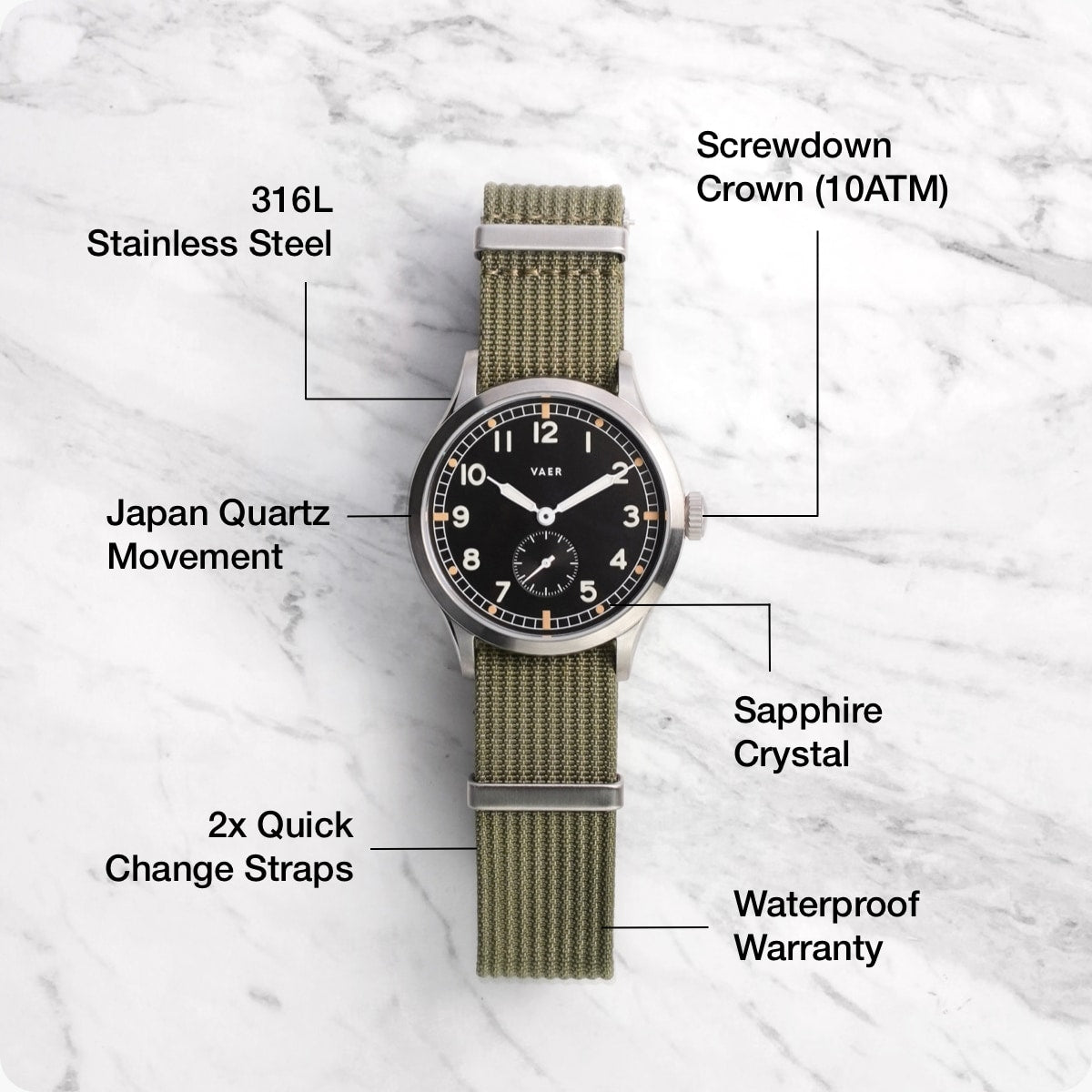

Our use of Ameriquartz movements in watches like the new Vaer C3 and C5 Dirty Dozen field watches represents a significant reinvestment in American watch manufacturing capabilities. By partnering with FTS, we are not only reviving a storied tradition but also pushing the boundaries of what is possible in American watchmaking.

This Memorial Day, as we honor the legacy of those who have served our country, we also celebrate the spirit of innovation and craftsmanship that continues to drive us forward. Our FTS Ameriquartz movements are more than just a testament to precision and reliability; they are a symbol of our commitment to American manufacturing and the enduring value of technical craftsmanship.