The Perfect Everyday Timepieces

American Assembled Watches

Vaer started Vaer in 2016 with a simple goal: build timeless, affordable, and waterproof watches. Soon after, we expanded that vision to include American craftsmanship—beginning with locally made leather straps and growing into U.S.-based assembly.

Today, we’re proud to offer some of the most affordable USA-assembled watches on the market, the most American quartz watches (by U.S.-origin content), and the widest range of USA-assembled movement options—giving customers the choice of USA-built quartz, solar quartz, and automatics.

Field Watches

- Slim, low profile fit

- 36mm & 40mm sizing

- Our most popular style

Dive Watches

- Rugged & Impactful

- 38mm, 39mm, 42mm size

- Ready for Action

Chrono Watches

- Retro & Colorful

- 38mm & 42mm sizing

- Big Impact 70s Style

GMT Watches

- Dual Timezone Function

- 39mm sizing

- Quartz & Automatic

The Most Popular Choices

American-Assembled Bestsellers

Our bestsellers. All assembled here in America.

50,000+

USA Assembled Watches

64%

Total USA Source Origin*

*For the C5 Dirty Dozen with Horween Leather

$259

Base Price for USA Watches

Powered By The Sun — The Easiest Choice

American Solar Field Watches

The perfect US-assembled off-grid tool watch that will keep you on time in the toughest conditions, without battery changes.

Powered by Your Motion — The Enthusiast's Choice

American Automatic Watches

The perfect off-grid tool watch that will keep you on-time, without the need for battery changes.

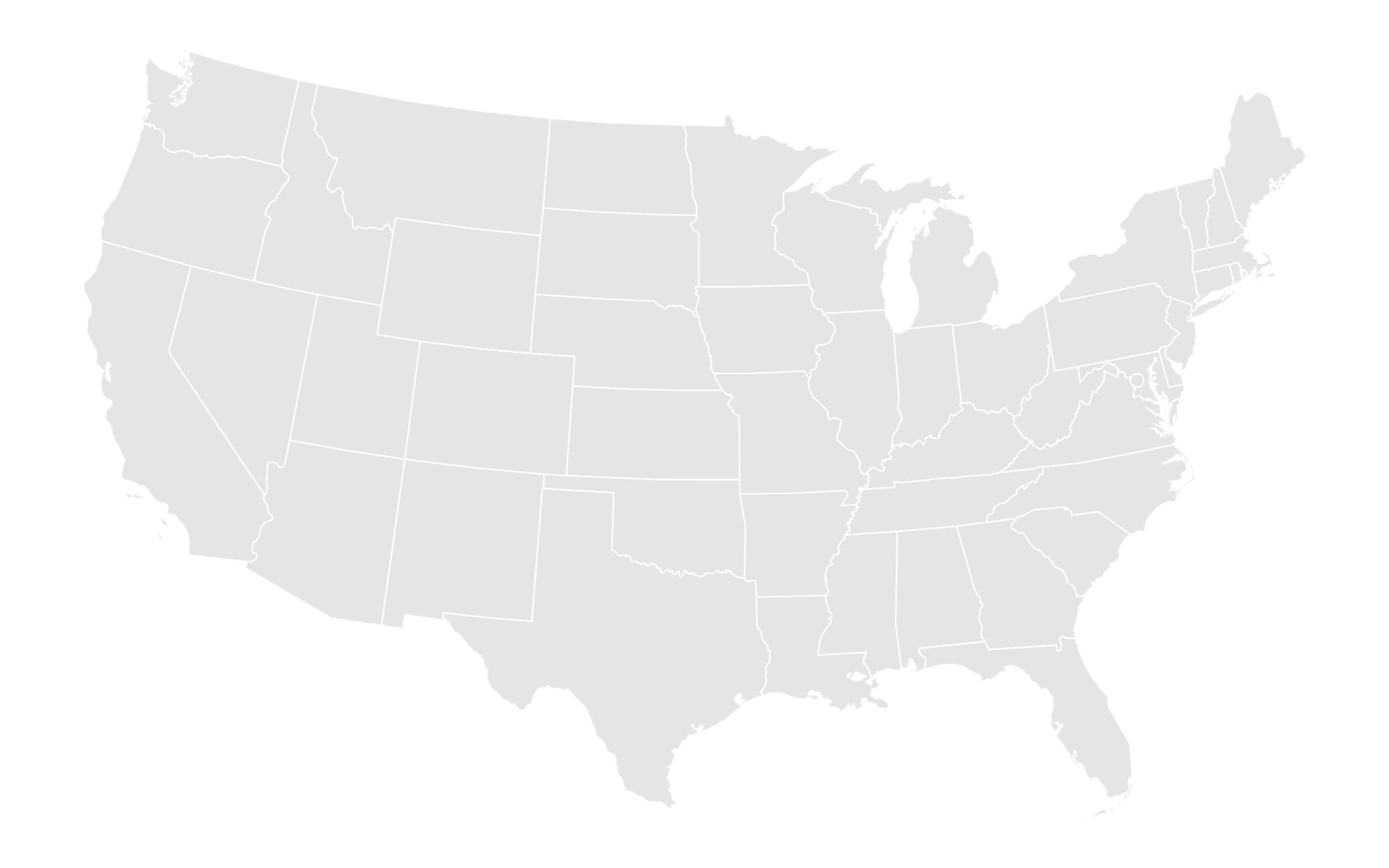

Los Angeles, CA

Vaer is operated and headquartered in Los Angeles, and it remains our central production, assembly and quality-control hub.

Chicago, IL

Our USA-made leather straps are tanned in Illinois by the Horween Leather Company which has been operated by the same family for over 100 years.

Tampa, FL

Our USA-made leather straps are cut and sewn in Florida by a team of skilled technicians.

Kansas City, MO

In 2023 we brought our fulfillment in-house, opening and staffing our own warehouse in the middle of the American heartland.

Scottsdale, AZ

In addition to our core team in Los Angeles, we work with multiple assembly teams around the country, including our long-time partner FTS in Arizona. FTS is also the supplier of our USA-built Ameriquartz movements.

Powered By The Sun — Inspired by Vintage Divers

American Solar Divers

The Vaer DS2 Diver is our most affordable dive watch, combining classic tool-watch design with 150 meters of water resistance, a screw-down crown—all in a compact, adventure-ready package.

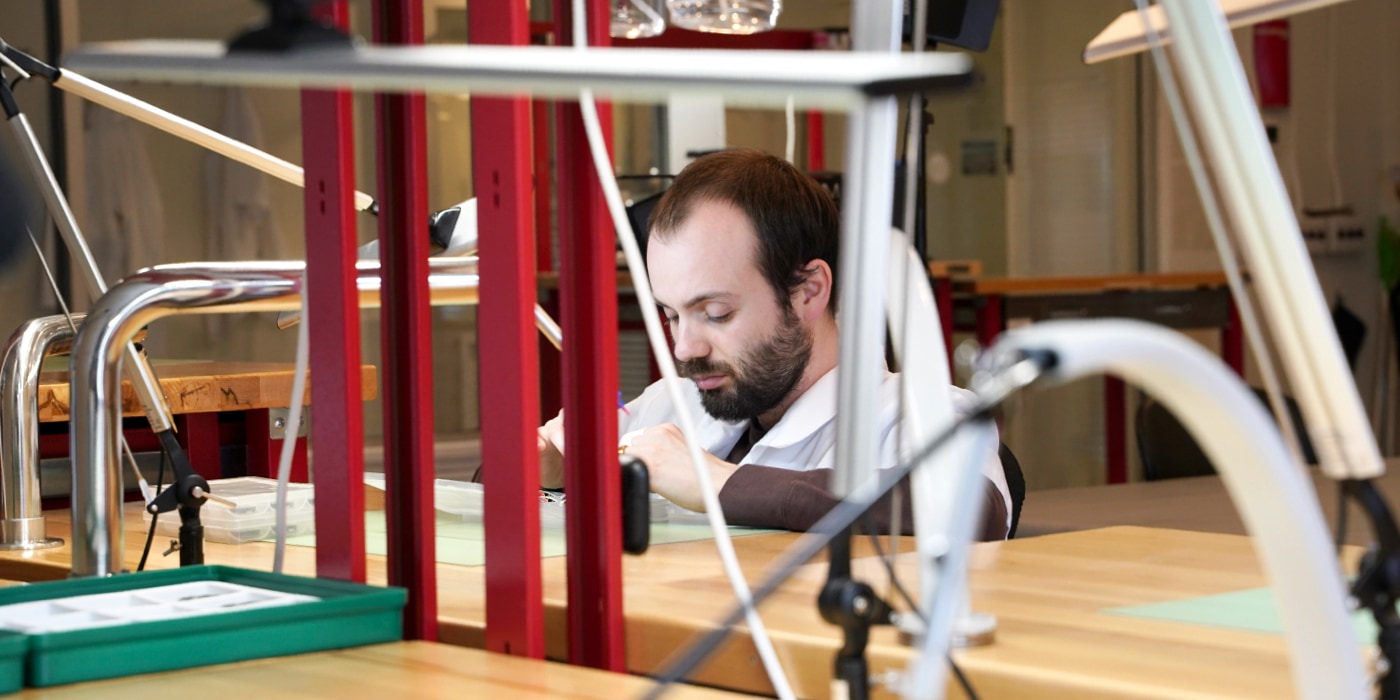

A Dedication to Detail

From day one we’ve been committed to the goal of supporting skilled craftsmanship and local production in the United States. It's certainly not without its challenges (and costs) but we truly believe that local assembly makes us better product designers and business operators.

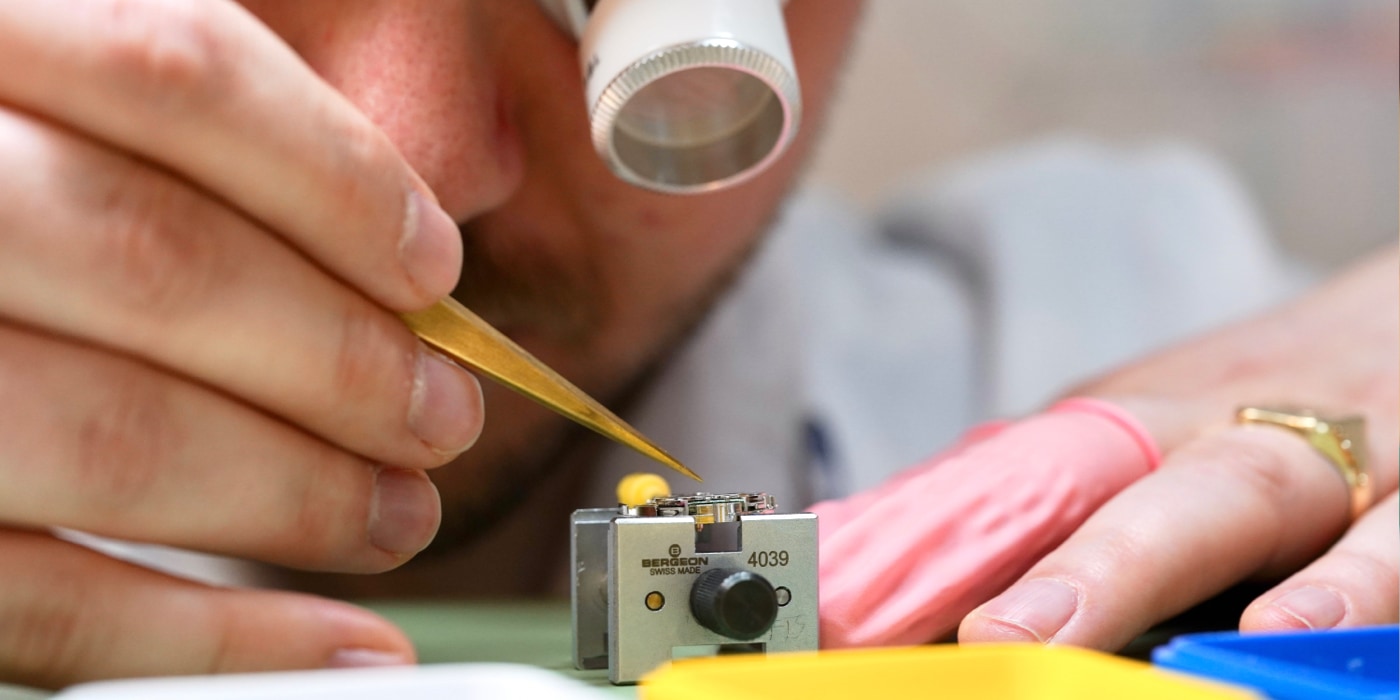

We don't come from a long line of watchmakers, we didn't have any industry connections, and prior to starting Vaer, we didn't have any experience working in the retail industry. Our commitment to US-sourcing has allowed us to learn on the job, helping us understand our supply chain from end-to-end, and form a deep connection to our products. This level of involvement has yielded countless product design improvements, from pinion height and dial spacing optimizations to hand-torque adjustments, and stem length regulation.

While we aren't skilled enough to put together a watch ourselves, we love brainstorming with our US technicians on how we can streamline the assembly process, save them time, and improve the functionality and design of our products.

Ameriquartz Movements — Racing Inspired

American Chronographs

Blending vintage motorsport style with modern durability, delivering precision timing and bold wrist presence.

Perfect For Travellers

American GMT Watches

Combining rugged, ocean-ready durability with dual-timezone functionality, offering a versatile travel companion.

Learn More on the Vaer Blog

Our USA assembly process is a reflection of our dedication to quality and our commitment to maintaining the highest standards in watchmaking. It’s a complex, detailed operation that ensures every Vaer watch is not only a functional tool but a impressive representation of American craftsmanship.

Read MoreLearn More on the Vaer Blog

Our use of Ameriquartz movements in watches like the new Vaer C3 and C5 Dirty Dozen field watches represents a significant reinvestment in American watch manufacturing capabilities. By partnering with FTS, we are not only reviving a storied tradition but also pushing the boundaries of what is possible in American watchmaking.

Read MoreLearn More on the Vaer Blog

Like our watches, ensuring best-in-class leather quality means focusing on the details and doing the little things right. We've worked to constantly improve and refine our leather products, and we're incredibly proud of the quality, craftsmanship and source origin of our current offering.

Read More